Blue Sky Roadmap Report Phase V- The Rebound of Fall and Winter Air Pollution: Inspecting “Differentiated” Management

by the Institute of Public & Environmental Affairs - April 2019

Translator’s Note: The following report has been translated for the purposes of reference only. For original quotes, a full list of the 74 enterprises contacted and their violation records as listed in the Blue Map database, please refer to the Chinese version of this report.

In the autumn and winter of 2018-2019, many key regions experienced a year-on-year rebound in atmospheric pollution. At the same time, there was also a rebound in the output of high emissions industries, including iron, steel and coking. Is the substantial increase in output by some steel companies with previous regulatory violations consistent with the original intent of “differentiated” management? 1 In the context of “steady growth”, how will regions avoid returning to “one-size-fits-all” policies?

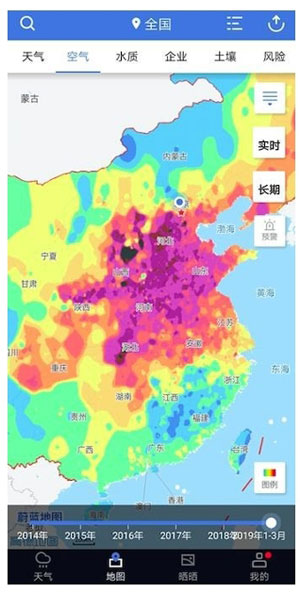

Click to see the National Dynamic Air Quality Map for November 2018 to February 2019 (Chinese)

Smog returned to many key regions in the autumn and winter

Looking back at the recent 2018-2019 autumn and winter seasons, we see that from November 2018 to early March 2019, the Jing-Jin-Ji and its surrounding regions, the FenWei plain, and parts of Central and Eastern China all experienced multiple incidents of heavily polluted weather. Taking January 2019 as an example, across 168 of the country’s key cities, more than 100 cities saw a rise in PM2.5 levels. On average, the percentage of good air quality days was 35.3% for the “2+26” cities of the Jing-JinJi region and its surrounding regions, a decline of 13.9% from the previous year, while average PM2.5 levels were recorded at 108 micrograms per cubic meter, an increase of 16.1% year-on-year. On average, the percentage of good air quality days for 11 key cities on the Fen-Wei plain was 28.2%, a decrease of 3.0% against the same period last year. The average concentration of PM2.5 on the Fen-Wei plain was 128 micrograms per cubic meter, up 16.4%

year-on-year.

Between October 2018 and January 2019, the average PM2.5 level of the “2+26” cities increased 6.7%. Among them, 22 cities saw their average concentration of PM2.5 rise rather than fall.

According to an analysis by the Ministry of Ecology and Environment's (MEE’s) China National Environmental Monitoring Center, unfavorable meteorological conditions are an external cause of regional pollution.2 However, a more important direct cause is still the huge rebound of regional emissions output from energy-intensive industries, which has surpassed the environment's capacity for these pollutants.

Winning the battle for blue skies is the top priority for 2020 pollution response efforts. For this reason, the MEE has established four key points of action, namely that the key pollution indicator to control is PM2.5; the key regions are the Jing-Jin-Ji region, the Yangtze River and the Fen-Wei plain; the key period includes the autumn, winter and start of spring; and the key industries and areas of focus are iron, steel, thermal power, building materials and other industries, as well as ‘dispersed’ enterprises, ‘dispersed’ coal, diesel trucks and dust control, among other areas.3

In this context, we analyzed the emissions and environmental performance of heavily polluting industries including iron, steel and coking in key regions. We can see that after the mandatory production limits and halts of the past, the question of how to effectively implement “differentiated management”, avoid “one-size-fits-all” policies, and stop polluting companies from seizing the opportunity to rebound and sharply increase their production is the greatest challenge facing these key regions. This question may indeed determine the success or failure of the battle for blue skies.

Iron, steel and coking industry production rebounded from last year

The iron and steel industry is an energy-intensive, heavily polluting, high-emissions industry. The iron and steel smelting process consumes large amounts of ore, fuel and other raw materials, and the primary production operations involve sintering, smelting and steelmaking. Different types of air pollutants are produced during the transportation of raw materials and fuel, loading and unloading, processing and smelting. In short, the iron and steel industry produces a high volume and many types of different pollutants. In 2015, the iron and steel industry emitted 12.4%, 9.6% and 32.2% of the total national industrial emissions for sulfur oxide, nitrogen oxide and particulate matter, respectively. With the exception of nitrogen oxide, the iron and steel industry accounted for far more emissions of the two other major pollutants than any other major industry aside from electricity.4

Our investigation found that during the autumn and winter of 2018, compared to the same period in 2017, one of the most significant changes was the resurgence of the iron and steel industry's year-on-year output.

Taking the primary battlefield for pollution prevention and control, Hebei Province, as an example, data from the National Bureau of Statistics (NBS) finds that Hebei Province produced 237 million tons of crude steel in 2018, maintaining first place in the country for crude steel production and increasing its output by 0.8%.5,6 While this increase may seem limited, it is only an annual average.

According to data from the China Industrial & Commercial Research Institute, crude steel production in Hebei Province decreased during the first three months of 2018 compared to the same period the previous year. In October, November and December, however, production increased significantly against the same period in 2017, wherein November output increased more than 20% year-on-year.7

Data from the National Bureau of Statistics on March 14 showed that from January to February 2019, the national average daily steel output was 2.906 million tons and crude steel output totaled 14.958 million tons, with a 9.2% increase from the same period last year. Total steel output reached 171.46 million tons overall, yielding a year-on-year increase of 10.7%. 8 Hebei Province alone produced 37.311 million tons of crude steel, a year-on-year increase of 17.3%, and remained the country's leading producer.9

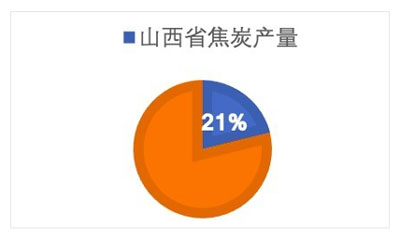

As the iron smelting process uses large quantities of coke, the coking process can also be broadly classified as part of the iron and steel industry. Coking uses coal as a raw material to obtain coke through carbonization at high temperatures. According to the China Industry Information Network, in 2018, Shanxi Province produced 92.562 million tons of coke, accounting for approximately 21% of the country's total coke production.10

The China Industry Information Network database shows that between October and December 2018, Shanxi saw a remarkable increase in coke output compared to the same period in 2017.

The iron, steel and coking industries are not only responsible for heavy pollutant emissions, but also high energy consumption. A sharp rebound in output will therefore also lead to increased energy consumption. Because energy use is primarily supported by coal power, the increase in iron, steel and coke production also means an increase in coal-fired emissions.

It is in this context that the so-called "differentiated" management policy was put forth.

Production rebounded for some steel enterprises with existing environmental violation records

In September 2018, the MEE officially released the “Action Plan for the Comprehensive

Prevention and Control of Autumn and Winter Air Pollution in Beijing-Tianjin-Hebei and Surrounding Areas for 2018-2019”. Unlike the 2017 plan, the 2018 Action Plan does not require Shijiazhuang, Tangshan, Handan and other key cities to limit their iron and steel output with a

“50% production limit”. Some believe that removing this industry-wide production restriction is the primary reason for the substantial increase in iron and steel output.

However, the Action Plan does not really cancel this restriction, but rather requires regions to implement "differentiated" management with peak and off-peak production depending on their actual circumstances. The original intent of differentiated management is to prevent the oversimplified and rough "one-size-fits-all" approach. So-called "differentiation" means that enterprises with good environmental performance will not be affected, while those with poor environmental performance continue to face restrictions.

Despite this original intent, environmental violation records collected by the Blue Map and data from industry research organizations show us that many iron and steel companies with significant rebounds in production during the autumn and winter of 2018 were reprimanded by environmental protection bureaus (EPBs) for violating environmental regulations, both in the 2018-2019 autumn and winter and in previous years.

Blue Map satellite imagery shows that on-site environmental quality is extremely poor at some iron and steel enterprises.

There is no shortage of iron and steel enterprises that have been repeatedly found with environmental violations in Hebei Province. This investigation found problems such as open-air storage, direct emissions of dust, dust pollution and other common issues, which were potentially exacerbated by unfavorable weather conditions in the autumn and winter, leading to the “return of the smog” in these seasons.

Shanxi coke production rebounded, with similarly concerning corporate environmental performance

As in the iron and steel industry, the status of environmental noncompliance among “heavy emissions” coke manufacturers did not inspire optimism.

Among the enterprises in Shanxi Province in the Blue Map database, there were 453 companies with environmental records that share "coking" as a keyword.

Among them, many enterprises were found with air pollution issues under the increased supervision of key areas during the 2018-2019 Blue Sky protection efforts:

On December 12, an investigation discovered that the pollution control facilities of Fengda Coking Smelt Co., Ltd. were not working properly;12,13

On December 28, authorities found that Shanxi Xinsheng Coking Group Co., Ltd. had not implemented dust control measures for the site of its stockpiled material;14

On December 31, the online monitoring data for the Kangzhuang Coking Co., Ltd.’s coking furnace indicated that between December 27-31, 2018, the average concentration per hour of particulate matter in its exhaust emissions on several occasions surpassed the 30 micrograms per cubic meter limit of the "Emission standard of pollutants for coking chemical industry" (GB161712012).15

Six environmental organizations made inquiries, yet the majority of steel industry violators remained silent

In order to assist the implementation of differentiated management and guard against regions’ employment of one-size-fits-all policies, in January 2019, six environmental organizations – the Institute of Public and Environmental Affairs (IPE), Lvse Jiangnan, Kongqixia, Green Qilu, Green

Taihang and Qingyuan Huanbao – collectively sent a “letter to iron and steel enterprises

regarding pollution control in the fall, winter and early spring” to 74 iron and steel enterprises found with environmental violation records during this investigation. The letter reminded companies to pay attention to the air pollution situation in the autumn and winter of 2018 and to their previous environmental violation records. Companies were also encouraged to explain the reason for their violations and status of their rectification efforts and to perform better pollution control in the early spring.

Among the letter recipients, Hebei had the most companies, with 25 companies contacted. Next were Jiangsu and Shandong, with nine and six companies, respectively. Regrettably, as of April 15, 2019, the vast majority of these companies remained silent and provided no response.

Many of these 74 companies had or currently have severe pollution issues.

Taking Hebei Xinwu'an Iron and Steel Baking Steel Co., Ltd. as an example, on October 16, 2018, the Hebei EPB organized a special action for atmospheric environmental law enforcement for the 2018-2019 autumn and winter. An on-site inspection found the western outlet of the 1260-cubic meter blast furnace for baking molten iron and steel was not sealed, allowing some smoke and dust to be discharged directly into the air. Further, the online monitoring facility for the exhaust outlet of the sintering machine was not operating normally.16 The company was also punished several times in 2017-2018 for storing raw materials in the open air, among other violations.17

Statistical data from Mysteel.com shows that between October and December 2018, the company's crude steel output substantially increased from the same period last year. In October, its output doubled in comparison with 2017.

Similarly, during the 2018-2019 autumn and winter special environmental law enforcement operation on October 16, a number of issues were discovered at Qinghuangdao Hongxing Iron and Steel (hereinafter referred to as "Hongxing Iron and Steel"): pollution prevention facilities were missing at the slag hole of blast furnace No. 6, causing the partial direct emission of smoke from the packaging process; the upper transmission corridor was not properly sealed; dust collection and treatment facilities at the No.3 shaft furnace pellet silo were not operating properly, causing untreated smoke and dust emissions as raw materials were fed into the pelletizing process; and the No. 3, No.4 and No.5 sintering machines pushed ore into an open dust collector, causing the dust to overflow, among other issues.

Barely two months later, Hongxing Iron and Steel was once again investigated regarding a problem with the smoke and dust containment facilities of its No. 7 blast furnace, which released untreated smoke, dust and industrial emissions into the environment as slag was released through the slag-hole. The investigation found that the company's No.7 blast furnace slag-hole was not tightly sealed, precipitating a penalty from the EPB for untreated smoke and dust emissions.18

The Hebei EPB 2018-2019 autumn and winter environmental special environmental law enforcement operation also organized an investigation on October 26 at Tangshan Qian'an's Hebei Rongxin Iron and Steel Co., Ltd. (hereinafter referred to as Rongxin Iron and Steel) and found the following: the south side of the 10.5 square meter No. 2 shaft furnace discharge outlet was not sealed; one set of dust removal facilities was used for simultaneously filtering the No. 1 and No. 2 sintering units and a dust collector, leading to insufficient dust removal given the volume of air and the partial direct emissions of dust.19 Additionally, the Blue Map also include 24 environmental violation records for the company dated from 2015 to 2018.20 From October to December 2018, Rongxin Iron and Steel's year-on-year crude iron and steel output increased significantly.21

Innovative environmental governance starts with active corporate disclosures

Since the 2018 autumn and winter period, the return of smog to key air pollution regions – the "2+26" cities in the Jing-Jin-Ji and surrounding regions in particular – was no accident.

Facing pressure from the economic downturn and complex international and domestic circumstances, some regions have shown a sigh of relief when it comes to environmental management. In a routine press conference in January 2019, however, the MEE pointed out that environmental protection and economic development are not in direct opposition, but share a dialectical unity in their relationship. 2019 was a tough year in the battle for blue skies. In light of these challenges, we will thoroughly implement the decision-making and deployment orders of the Party Central Committee regarding the battle for blue skies in accordance with the general tone of stable progress by standing firm, consolidating results, coordinating economic development and environmental protection, and driving the continuous improvement of air quality across the country.22

At the second meeting of the 13th National People's Congress in March 2019, China's policymakers expressed a strategic determination to maintain environmental protection efforts, using staunch "bite the bullet" willpower and to "not quiver, not give up, not open the floodgates" but remain resolute. Only then can we promote forward steps for the environment and achieve new breakthroughs.23

Maintaining strong environmental protection strategies does not mean that environmental supervision measures do not need refining.

Just as Premier Li Keqiang requested in his Government Work Report, “reform and innovate environmental governance methods and supervise companies in accordance with laws and regulations, but also recognize the importance of reasonable demands, strengthen guidance and support, provide reasonable transition timelines to those in need of reform, and avoid oversimplified and rough management measures or reverting to the oversimplified method of closing factories down.”24

This request deserves the attention of all stakeholders. In particular, environmental authorities need to avoid “one-size-fits-all” administrative orders, strictly control pollution, punish enterprises that exceed emissions standards or violated environmental regulations in accordance with the law, truly implement “differentiated” management, and create a level playing field for law-abiding enterprises to win market competition.

At the same time, regulatory authorities also need to fully disclose regulatory information in order to better mobilize the capacity of all sectors of society, including the public supervision of environmental organizations and local residents, as well as market mechanisms, such as green finance and green supply chains. These methods have more flexibility than government law enforcement and can provide more services for the green transformation and development of companies.

But external change must start with internal change. Companies in high-emissions industries must strictly abide by relevant environmental laws and regulations and earnestly fulfill their responsibilities to environmental protection. They must also shoulder corporate social responsibility, continuously improve their performance and regain the trust of their communities and the public. All of this begins with corporate information disclosure.

Given that most steel companies evade questions regarding pollution, the active follow-up and information disclosure by several large iron and steel companies was extremely valuable.

Headquartered in Hebei, Delong Steel actively responded upon receiving the letter from the environmental groups. On October 24, the first round of the 2018-2019 autumn and winter special environmental law enforcement operation's investigative team found that Tangshan Delong Steel Co., Ltd. (hereinafter referred to as “Tangshan Delong”) illegally transported items during heavily polluted weather and stored construction soil for backfilling, desulfurization byproducts, and sludge from secondary dust removal in the open air. With no protective measures in place, the stored items discharged pollutants directly. In response, Tangshan Delong addressed the following in an explanatory document:

- The law enforcement inspection period was indeed an early warning period for heavily polluted weather; however, our company had an agreement with environmental officials that during heavy pollution early warning periods, in order to ensure safe production, 308 emergency material transportation vehicles could

- enter the factory site every day. After obtaining the vehicle information, the number of vehicles entering and leaving the factory on that day met the requirements for an early warning period for severely polluted weather.

- The construction soil for backfilling is in fact mud for the third phase of a water supply project, which will be used to backfill our company’s abandoned fish ponds. The desulfurization by-products and secondary dust removal sludge are all wet and therefore do not generate dust. After some initial dewatering, the byproducts and sludge will be transported to an enclosed yard for storage as sintering raw materials.25

The response letter from Liaoning's Anshan Iron and Steel Group Co., Ltd. is as follows:

- Between 2012 and 2014, our company phased out four 4-meter and four 5-meter outdated coking furnaces. In 2015, we built two modernized, environmentally friendly 7-meter coking furnaces (coking furnaces No. 9 and No. 10). In 2016, in accordance with provincial and city requirements to clean up and rectify construction projects with environmental violations, we commissioned a qualified environmental auditing agency to prepare the ‘Anshan Iron and Steel Coking System Environmental Assessment Report’ and obtained approval documents from the Anshan administrative examination and approval bureau. Now the formalities of this environmental protection project are complete.

- The No. 9 and No. 10 coking furnaces are equipped with the most advanced environmental protection facilities. During the construction process, they strictly adhered to the “three simultaneous procedures” and in order to adapt to improved standards, in 2017, the two coking furnaces were equipped with supporting flue gas desulfurization and denitrification facilities. An online monitoring system was also installed at the discharge outlet and connected to the government EPB network. No emissions have exceeded pollutant standards during operation.

Another company, Changshu Longteng Special Steel (hereinafter referred to as Longteng Special Steel), also responded. In 2016, the Changshu municipal people's government published pollution source air emissions monitoring data for provincial-level key pollution control facilities in Changshu. The data revealed that in September and October, smoke and dust from a Changshu Longteng Special Steel exhaust emissions outlet exceeded pollutant standards. In response, Changshu Longteng Special Steeel replied:

- …exhaust emissions from all of our environmental protection facilities are up to pollutant standards; present emissions concentration indicators are better than standard national emissions limits. When the environmental protection facilities operate abnormally during the production process, or when the exhaust emissions are abnormal, our company reports the occurrence to the local environmental protection bureau in a timely manner, and simultaneously stops production in a timely manner...

The new Environmental Protection Law stipulates nine major responsibilities for environmental protection by companies and points to the bare minimum for corporate survival and development as compliance with the law. To win the war against pollution and solve outstanding environmental issues, no business can simply wait for good luck or watch from the sidelines to avoid environmental management responsibilities. Steel enterprises with existing violations should take the initiative to bear the responsibility for environmental governance and to make public disclosures as to the causes and rectification of their violations as soon as possible. We also look forward to seeing enterprises with environmental violations explain their violations to the public, disclose their corrective actions, and consciously fulfill their social responsibility for environmental protection.

We hope all sectors can fully understand the importance of information disclosure to corporate environmental responsibility and promote corporate information disclosure as a prerequisite to implementing “differentiated” management. We look forward to collaboration between the government, businesses and the public to use information and intelligent strategies to innovate environmental government mechanisms, serving the green transformation and development of society and the economy.

Notes :

1 In March 2019, China began to implement a “differentiated” management approach to enforcing environmental regulation. This is a direct response to the “one-size-fits-all” approach in which some industries were asked to halt or slow their production, regardless of whether or not they followed environmental regulations. The new policy encourages greater discretion among local enforcers.

2 http://finance.sina.com.cn/roll/2019-02-27/doc-ihsxncvf8251508.shtml

3 ‘Dispersed’ coal refers to coal used in rural areas for heating, cooking and small-scale industry. ‘Dispersed’ enterprises refer to small or informal businesses, including stalls and mom-and-pop shops, which may lack standard pollution control facilities.

4 http://www.chyxx.com/industry/201802/613094.html

5 https://news.mysteel.com/19/0211/17/10C74C9BFAED5C0A.html

6 http://tjj.hebei.gov.cn/hetj/tjsj/ydsj/101547423601657.html

7 http://s.askci.com/news/chanxiao/20190130/1451231141094.shtml

8 http://www.stats.gov.cn/tjsj/zxfb/201903/t20190314_1653784.html

9 http://tjj.hebei.gov.cn/hetj/tjsj/ydsj/101548813276938.html

10 https://www.chyxx.com/shuju/201901/711746.html

11 http://s.askci.com/news/chanxiao/20190130/1544581141100.shtml

12 The report cites TianYanCha for the English names of companies for which English names could not be located on an official company website.

13 http://www.ipe.org.cn/IndustryRecord/regulatory-record.aspx?companyId=1901431&dataType=0&isyh=0

14 http://www.ipe.org.cn/IndustryRecord/regulatory-record.aspx?companyId=76240&dataType=0&isyh=0

15 http://www.ipe.org.cn/IndustryRecord/regulatory-record.aspx?companyId=3588676&dataType=0&isyh=0

16 http://www.hebhb.gov.cn/ztbd/dqhjwtbg/201810/t20181018_67745.html

17 http://www.ipe.org.cn/IndustryRecord/regulatory-record.aspx?companyId=177603&dataType=0&isyh=0

18 http://xzzf.hbzwfw.gov.cn/punish/getPunishById?id=3683756

19 http://www.hebhb.gov.cn/ztbd/dqhjwtbg/201810/t20181029_67988.html

20 http://www.ipe.org.cn/IndustryRecord/regulatory-record.aspx?companyId=238977&dataType=0&isyh=0

21 https://news.mysteel.com/19/0220/10/F8D3A44B2A16B8A6.html

22 https://baijiahao.baidu.com/s?id=1623344472992080345&wfr=spider&for=pc

23 http://opinion.people.com.cn/n1/2019/0305/c1003-30959418.html

24 http://www.gov.cn/zhuanti/2019qglh/2019zfzgbgdzs/img/2019e-book.pdf

25 http://www.ipe.org.cn/IndustryRecord/regulatory-record.aspx?companyId=183909&dataType=3&selfdata=record&isyh=0